Radiopharmaceuticals are emerging as a key drug class for the treatment and diagnosis of cancer. Theranostic medicines are used to diagnose and precisely deliver radiation therapy to destroy cancer cells. This type of personalized oncology treatment allows health care providers to better detect and treat patients, while reducing the risk and overall side effects compared to other treatments.

At SAGE, we understand the unique challenges associated with the production of alpha, beta, and gamma radiopharmaceuticals. These drugs are not only difficult to produce but are also highly regulated and require specialized facilities and equipment. With our technical knowledge and experience in this field, we can help our clients navigate challenges in the following areas:

Focus Area

Safety and Containment

Challenge

Operator safety from radiation and environmental containment

Focus Area

Sterile-injectables

Challenge

Manufacturing under aseptic conditions to protect the quality of the drug product, as well as meeting the requirements of Good Manufacturing Practice (GMP).

Focus Area

Supply Chain

Challenge

Manufacturing, packaging, testing, releasing, and transporting the drug to the patient before the radioisotope decays

Feature:

SAGE is proud to share that we have been featured in Business Focus Magazine (Issue 113). Within our editorial we highlight our strategic partnership with our client in the schematic and detailed design of their new state-of-the-art facility.

CLICK HERE TO READ MORE

Solutions

Facility Pre-Design and Construction

For clients that require a new radiopharmaceutical manufacturing space or modifications to existing facilities, SAGE can perform site/space evaluation, develop layout drawings, and prepare a pre-design package that incorporates radiation safety and aseptic manufacturing requirements to meet regulatory standards. We work closely with our clients to ensure seamless collaboration with their chosen facility design team. We consider factors such as shielding, layout optimization, radiation monitoring and environmental controls to protect personnel, while also ensuring the highest level of product quality.

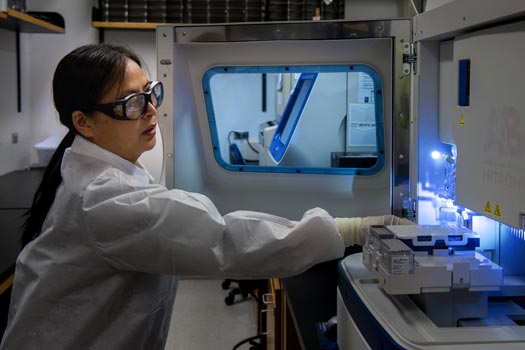

Equipment Selection

For clients that require commercial process and/or lab-scale radiopharma equipment, SAGE can provide expert guidance to develop equipment specifications, engage with specialized vendors for equipment and systems (radiation monitoring, shielded isolators, hot cells for clinical and commercial scale operations) and manage the overall procurement process.

Selecting the right equipment is crucial for successful radiopharmaceutical production and handling operations. Our in-depth knowledge of the latest technologies ensures that our clients benefit from state-of-the-art equipment that protects personnel and the environment, enhances productivity, and meets regulatory requirements.

Integrated Project Delivery

SAGE understands the importance of project management to deliver a project efficiently and successfully from end to end, as well as the need to tailor processes to each client’s specific needs when required. From procurement, installation, commissioning and qualification of equipment and facilities, to support of product commercialization, Process Validation batches and PAI readiness, the SAGE team can bridge the gap between all stakeholders to ensure a successful outcome for the project.

Our Services

Equipment Engineering

- Drawing Review

- Process and Software Workflows

- Equipment Specifications and Procurement

- Packaging Specifications

- FMEA

- Equipment User Requirements Specifications – Vendor Management

Compliance & Validation

- Technical Review – Process Control Strategy

- IQ/OQ/PQ – Cleanroom Smoke Studies

- Max Occupancy Studies – Temperature Mapping – SOPs

- Logistics Auditing

Project Management

- Due Diligence Reviews

- Engineering Standards Assessment

- Forecast Review

- Facility Refurbishment Management

Key Projects

New state-of-the-art facility for multiple radioisotopes and radiopharmaceuticals

New multi-isotope radiopharmaceutical facility

Managed the project for a brownfield parenteral radiopharmaceutical facility with requirements for radiation safety and aseptic manufacturing. Collaborated with the client and RSO, prepared facility concepts, user and performance specifications for a multi-isotope facility, ensuring appropriate equipment selection, shielding, ventilation, and radiation waste storage solutions. Acted as the client’s representative during the detailed design phase.

New clinical radiopharmaceutical manufacturing space within an existing facility

Assessed suitable locations, generated layout concepts for new cleanrooms and issued tenders for the design team and construction management services. Equipment vendor management and owner’s representative during design and construction. Cleanroom, shielded isolator, and hot cell specification and validation.

New clinical-scale radiopharmaceutical manufacturing and processing suite

Provided technical input for selection, design, and installation of hot cells and shielded isolators. Contributed to the initial layout development to suit end users’ needs. Liaised with the construction PM for specialty equipment installation and managed hot cell vendors.

New automated high-volume radiopharmaceutical hot cell production line from synthesis, compounding to aseptic filling and packing

Provided technical and equipment design guidance, supported procurement, managed vendors, oversaw hot cell fabrication surveillance reporting, coordinated facility integration, defined process workflows, and provided input for consumables kit design.

New fully automated high-volume radiopharmaceutical tertiary packaging line

Provided technical and procurement support, defined workflows, created specifications to meet nuclear regulatory shipping requirements for up to Yellow III packages, and oversaw vendor selection for a complex equipment solution.

Commercialization of multiple radiopharmaceutical products

Led overarching program and project management, created and managed integrated cross-functional project plans up to ANDA submission.

Implementation of radioisotope production at an existing facility

Provided technical and project management support for equipment procurement, commissioning, and qualification. Coordinated with vendors and managed tasks for method validation and robustness studies.