With a thorough understanding of Lean and Six Sigma principles, SAGE is able to effectively incorporate such methodologies into Continuous Improvement projects for manufacturers in the regulated industries.

“Leaning” out processes will reduce waste, allowing the process to flow more efficiently to the customer. The regulated industries are laden with tasks that satisfy regulators rather than directly adding value to the customer. SAGE can support projects by analyzing existing processes to appropriately identify waste that can be eliminated while retaining tasks that are essential to regulators, end users, and our customers.

Six Sigma methodology seeks to reduce defects in a process, such that the outputs are known and repeatable units every time. This approach pairs seamlessly with regulated industries where Safety, Identity, Strength, Purity, Quality (SISPQ) are paramount to the end product.

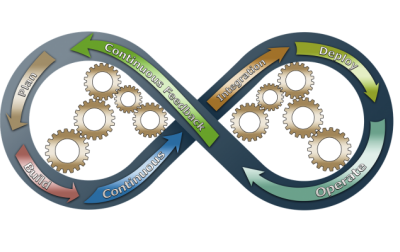

Our Continuous Improvement Strategy

SAGE utilizes in-house expertise to apply Lean and Six Sigma principles to Continuous Improvement projects, through a 5-stage approach:

define

- Define the problem, improvement activity, or opportunity for improvement

- Define the project goals and customer requirements

- Define project boundaries

- Define the process by mapping the process flow

- Identify value in the eyes of the customer

measure

- Develop a data collection plan for the process

- Collect data to determine types of defects and metrics

analyze

- Identify gaps between current performance and goal performance

- Root cause analysis

- Prioritize improvement opportunities

- Identify sources of variation

improve

- Create innovative solutions

- Develop and deploy implementation plan

control

- Implement measures to prevent reverting back to the “old way”

- Development and implement an ongoing monitoring plan

Key Projects

Equipment & Facility Engineering

Process

Process mapping and optimization for a meal kit delivery company

OEE

Overall Equipment Effectiveness Study for two solid-dose filling and packaging lines

Compliance & Validation

Documentation

Site-wide review and optimization of standard operating procedures and document templates

Project Management

Documentation

Site-wide review and optimization of maintenance task lists and work order format